Fundamentals of Worm Gearbox Design

Fundamentals of Worm Drive Design

Advantages of a Worm Drive

- High gearbox ratio capability

- Reverse breaking design capability

- Compact gearbox design for tight spaces

- High output torque generation

- Low noise generation

- Large gearbox shock capability

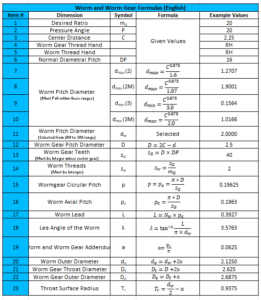

To begin calculating the geometry for a worm and worm gear, you must establish some baseline parameters. These can be roughly estimated just as a starting point. These following given values are required to begin working through the formulas; desired gear ratio, pressure angle, center distance, hand direction of thread, diametral pitch “normal diametral pitch”.

With determining these given values, please note that the worm and worm gear must have the same hand direction, diametral pitch and pressure angle. As you work through the following formulas you will see these generate two parts having a matching pitch, lead and lead angle. All of these parameters must match in order to have a worm mesh that operates smoothly without interference or binding.

Reference Table 1 as an example of how to generate the macro geometry for a worm and worm drive system.

Table 1

If you have any questions on this material or need support with your design please use the “Contact Us” form below and one of our associates will be in touch.

Customer Service

Covalo Industries provides experts in custom gear design. Our innovation can be found in various industries built on power systems and precision. Covalo’s sales and engineering support teams are ready to assist you, with your gear motor application. Contact us today for a quotation, application support and custom product configuration. Follow the request a quote link to speak with us.