Industrial Automation

Industrial Automation

Covalo Industries offers the design, testing and manufacturing of high precision industrial grade gearboxes, gearhead motors, linear/rotary actuators and speed or motion controllers. Industrial equipment faces some of the most demanding conditions. Gear boxes for automation machines must be durable and true to their life expectancy.

Our team is dedicated to our products and will support the application from initial development to service support. We design our custom gears, gear motors and gearboxes with materials and components which will guarantee a specific operating life. Best practices and analysis and key for producing a robust gear box that will hold up under high cycles. We are constantly improving and developing our gear design tools for higher levels of confidence per industry standards.

Our Team will be with you every step of the process when bringing your robot to market. Covalo Industries offers commitment through the development and product life. Staring with initial concept to certification testing and field service support.

Product Highlights

Gear Reduction Motors for Transfer Systems

Industrial conveyor systems require rigid and durable gear motors. Our gear boxes can be designed to the peak load conditions of their corresponding motors. We offer gearhead motor configurations or can retro fit your current AC or DC motor.

Robotic Joint with a Fully Reversing Worm Drive

Industrial robotics have demanding requirements for range of motion and power. Covalo industries offers various gear reducers such as worm gear boxes, angular bevel gear sets and planetary gear reducers. Production lines must remain running and we have the hardware that can keep volume high and downtime low.

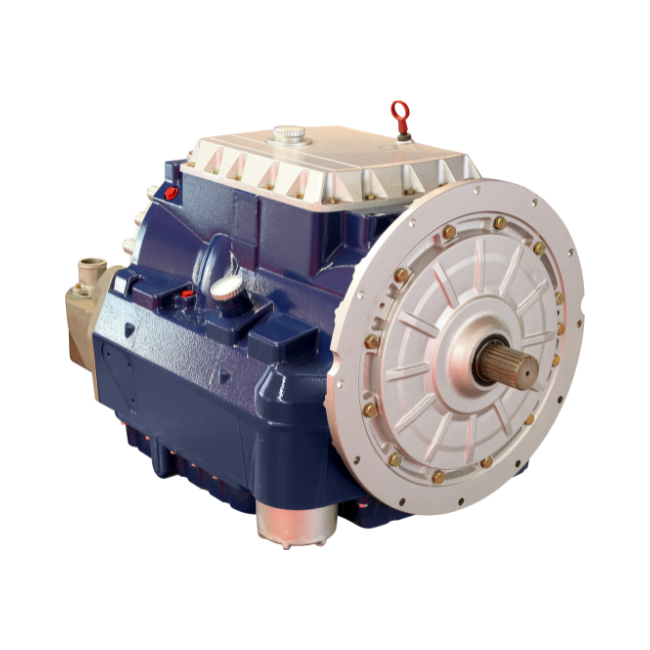

Robust Machine Gear box

Industrial machines must produce high power under relentless conditions. Our custom gear design tools allow us analysis various load conditions in minutes. We can guarantee a gear box which can heavy loading and zero service until replacement.

Customer Service

Covalo Industries provides experts in custom gear design. Our innovation can be found in various industries built on power systems and precision. Covalo’s sales and engineering support teams are ready to assist you, with your gear motor application. Contact us today for a quotation, application support and custom product configuration. Follow the request a quote link to speak with us.