Grow your Knowledge on Idler Gear Design

The Idler Gear

How to effectively incorporate an idler gear into a gear train. The idler gear is a well-known gear used within machines, but it has been found to be a misunderstood component as well.

What is an Idler gear?

Idler gears are located between a driving gear and a driven gear in a transmission or gearbox assembly, shown gear 3 in Figure 1 below.

What is an idler gear used for?

The main purpose of these gears within gearboxes are to span a gaps between the driver and driven gears and change the rotational direction of the driven gear. Let’s break this statement down a bit further.

Depending on your mechanical systems layout, the gears may have to be positioned a specific distance from each other to deliver the desired output, shown in Figure 2: Gear Span. This is a common situation where an idler gear should be incorporated in the gear train.

The other design point of the original statement is to incorporate an idler gear for rotational purposes. When two gears are in mesh, they will rotate in opposite directions. This may be an issue for your gearbox if the output rotation must be the same as the input.

See Figure 4: Opposite Rotating Gears for an example of how gear 2 (driver) rotates clockwise, which makes gear 3 (driven) rotate counterclockwise. But once an idler gear is inserted gear 2 (driver) rotates clockwise and gear 4 (driven) also rotates clockwise, as shown in Figure 5: Idler Gear Rotational Change.

This is a pretty simple concept for application purposes huh? Well, let’s now discuss some of the misconceptions of idler gears and how that can affect your gearbox design.

Misconceptions

Let’s start out with the most common question asked about idler gears. Do idler gears affect speed? The simple answer to this is “no they do not”. If you are designing a gearbox and calculating the ratios, do not include the idler gear in that formula. Regardless of the size or tooth count, its rotational speed cancels itself out as shown in Equation 1: Idler Gear Speed Ratio and Figure 6: Idler Gear Example. The gear trains ratio is dependent upon the output gear and the input gear.

Gear Train Speed Ratio Formula

m = speed ratio

Z2 = Gear #2 Tooth Count

Z3 = Gear #3 Tooth Count

Z4 = Gear #4 Tooth Count

The second commonly asked question about idler gears is, “Do idler gears affect torque?”. When calculating the torque within a gear train, the input torque must be multiplied by the output ratio as shown in Equation 2: Gear Train Output Torque. The idler gear does not affect the torque because of what was shown in Equation 1: Idler Gear Speed Ratio. Since the gear trains ratio is the output gear teeth divided by the input gear teeth, the idler is cancelled out from the equation.

Output Torque Formula:

Tout = Torque Output (in-lb)

Tin = Torque Input = 150 in-lb

M = Gear Train Ratio = 1.58

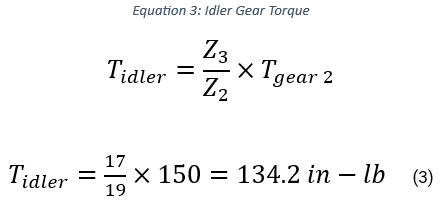

Just to really make this hit home, let’s break down the equations for calculating the torque. As previously stated, the output torque is the ratio multiplied by the input torque (driver gear). Equation 3: Idler Gear Torque below will treat the idler gear as it is producing an output torque.

Torque:

Tidler = Idler gear torque output (in-lb)

Z3 = Idler Gear Teeth = 17

Z2 = Driver Gear Teeth (Gear #2) = 19

Tgear 2 = Input Torque (Gear #2) = 150 in -lb

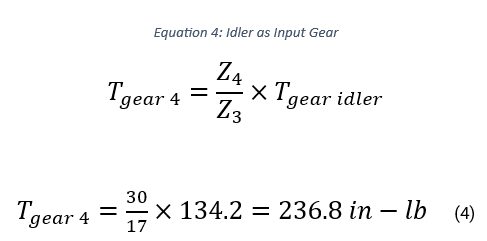

Equation 4: Idler as Input Gear below will now treat gear 4 as the output and the idler gear as it is the input within the system.

Gear #4 Torque:

Tgear 4 = Gear #4 torque output (in-lb)

Z3 = Idler Gear Teeth = 17

Z4= Driven Gear Teeth (Gear #4) = 30

Tidler gear = Input Torque = 134.2 in-lb

If you compare the torque output value calculated in Equation 4: Idler as Input Gear to that of Equation 2: Gear Train Output Torque, it can be seen the values are equal. This again demonstrates how the idler gear cancels out from the gear train.

Idler gear is very useful when fully understood and utilized correctly. There are various aspects of designing idler gears that must be considered, which span past the detail in this article. Here at Covalo Industries we enjoy solving gear application problems and sharing our knowledge to support your project. Our experience and internal engineering standard work make our design process very efficient to help bring your product to market. Feel free to reach out to us today if you have any questions regarding this article or our capabilities.

For more information contact us here