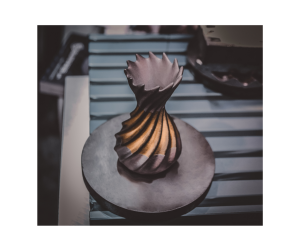

Metal 3D Printed Gears

Over the years, 3D printing technology has been increasingly popular in manufacturing industries and design-engineering. As the engineering industry progresses, it can be anticipated that more 3D printing and 3D printed metal gears will be widely available for production. Therefore, it is important for manufacturing engineers and teams to understand gear design for printed metal gears, and how this solution may be an option for end-use parts. Keep reading to learn more about 3D printed gears and the benefits this technology provides.

Since 1913, when Henry Ford launched the assembly line, industries have been searching for answers on how to reduce manufacturing costs and production times. Many developments have been implemented since Ford’s assembly line, from techniques like: lean manufacturing, robotics, and automated production. And even though 3D printing was introduced in the 80’s, only now have we begun to use 3D printing as an advanced method for producing end-use products.

So, “How do you 3D print a reliable metal part instead of machining one, a tried-and-true method?”

At Covalo Industries, we seek to assert our position ahead of a prospering industry of 3D manufacturing, designing metal 3D printed gears, and custom carbon fiber parts. Built with the focus on enhanced methods of manufacturing, 3D printed metal is proven to produce reliable parts, sometimes even stronger than traditional manufactured gears.

Two methods of 3D manufacturing are Selective Laser Melting (SLM) and Direct Metal Laser Sintering (DMLS). As metal additive manufacturing processes that involve powder bed fusion 3D printing, their particle bonding processes determine their differences as follows:

SLM uses metal powders with single-melting temperatures. SLM fully melts the particles, while in DMLS, the powder contains materials with variable melting temperatures. DMLS powders fuse on a molecular level, typically at elevated temperatures.

Basically, this means SLM produces parts from a single metal, while DMLS produces parts from various metals and their alloys.

Using these manufacturing processes (SLM, DMLS) and understanding the benefits and setbacks allows manufacturers to push engineering technology forward. 3D printed metal gears have the potential to reduce lead times significantly depending upon requirements, precision needs, and their application. The ability to eliminate machine set-ups, reduce the need for tooling, and decrease programming costs for a finished product in comparison in pricing to a traditional machined gear. 3D printed metals have the same processing capabilities as heat treatment, plating and precision machining but 3D printing allows for complex geometric parts with minimal processing cost.

As the industry continues to test and fine tune the 3D printing process, Covalo will push the industry forward with low-cost, end-use products. Assisting to reach the industry’s economic goals with clean-electric transportation, and low fuel usage will remain one of our top priorities as we grow as a company. With the assistance of our printers and composites, we can continue these efforts in exploring more efficient engineering for manufacturing.

Follow along for more updates from us, or reach out today to start your next project.