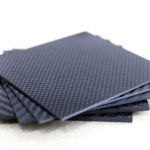

1st Quality Carbon Fiber Plain Weave 3k 50″

$40.00

This plain weave fabric has a width of 50″ and is sold in linear yards segments. It is woven in a 1×1 twill weave and has a 3k tow. This is our top selected fabric for automotive part fabrication. The material is a 1st Quality, in meaning it has zero flaws or defects. If handled properly during fabrication it will leave your part with a stunning finish. This weave is ideal for resin infusion, wet lay-up and skinning parts.

You will need the appropriate resin or epoxy to properly cure/harden your part.

- Description

- Additional information

- 3D VIEW

- DRAWING/SPECIFICATION

- DESIGN TOOLS

- CATALOG

- Attachment

Description

What Is Carbon Fiber Fabric?

Carbon Fiber fabric is yarns of carbon fiber twisted together to form a tow. The carbon fiber tow is then woven together with other identical tow to form a cloth. This cloth is similar in appearance to any other fabric. The difference lies with how the weave is coarser than a section of cotton fabric.

How Do You Make Parts with Carbon Fiber Fabric?

Since carbon fiber fabric begins as a flexible material, the fabric requires a binding agent for it to become a rigid body. This binding process is what creates the classification of composite material. In order to obtain the full properties of a composite material two parts are necessary. Carbon fiber fabric requires a matrix or resin to complete this process. The most commonly used are epoxy resins or vinyl resins. With our standard carbon fiber fabric, the material is laid onto a mold where the resin is introduced to the fabric. When the carbon fiber fabric and resin fully cure into their composite state, the part will produce the shape of the mold.

Understanding the different weaves of Carbon Fiber Fabric?

Carbon fiber fabrics have different weave patterns based upon their application. Here are some listed below…

Twill weave – 2×2 and 4×4 patterns which are ideal with forming complex shapes and maintaining stability. This is the most commonly used fabric because of its diagonal weave appearance. This is also the recommended carbon fiber fabric for skinning parts because it maintains its pattern over sharp edges.

Plain weave – 1×1 pattern which possesses a tighter interlacing of fabric. Plain weave carbon fiber is easier to handle because the tight interlacing prevents fabric distortion. This does not make it an ideal material for complex shapes because the fabric is stiffer. Plain weave carbon fiber fabric is ideal for fabricated flat plates and tubes.

Uni-directional weave – Hence the name this carbon fiber fabric does not have a weave pattern. All fibers are running together in a parallel form. This material is ideal for adding strength to your part. Based on part stress contours, sections of this material can be oriented in different angular directions, during your lay-up to give high tensile reinforcement.

Satin weave – Are known for their high level of flexibility. Similar to twill weave this carbon fiber fabric is first choice for highly complex geometries. This high level of flexibility, causes losses in fabric stability. Correct angular orientation is a priority when fabricating a structural part, in order to maintain part strength.

Additional information

| Weight | 0.680 kg |

|---|---|

| Fabric Quality Grade | 1st Quality |

| Fabric Length Segments | Linear yard |

| Fabric Width | 50" |

| Tow Size | 3k |

| Weave Pattern | Plain Weave |

| Modulus | Standard Modulus |

| Fabric Thickness | .010" |